Guía completa de la máquina de pesaje y envasado de bolsas prefabricadas con elevador tipo Z para productos granulados

The Comprehensive Guide to Z-Type Elevator Pre-Made Pouch Weighing and Packaging Machine for Granular Products

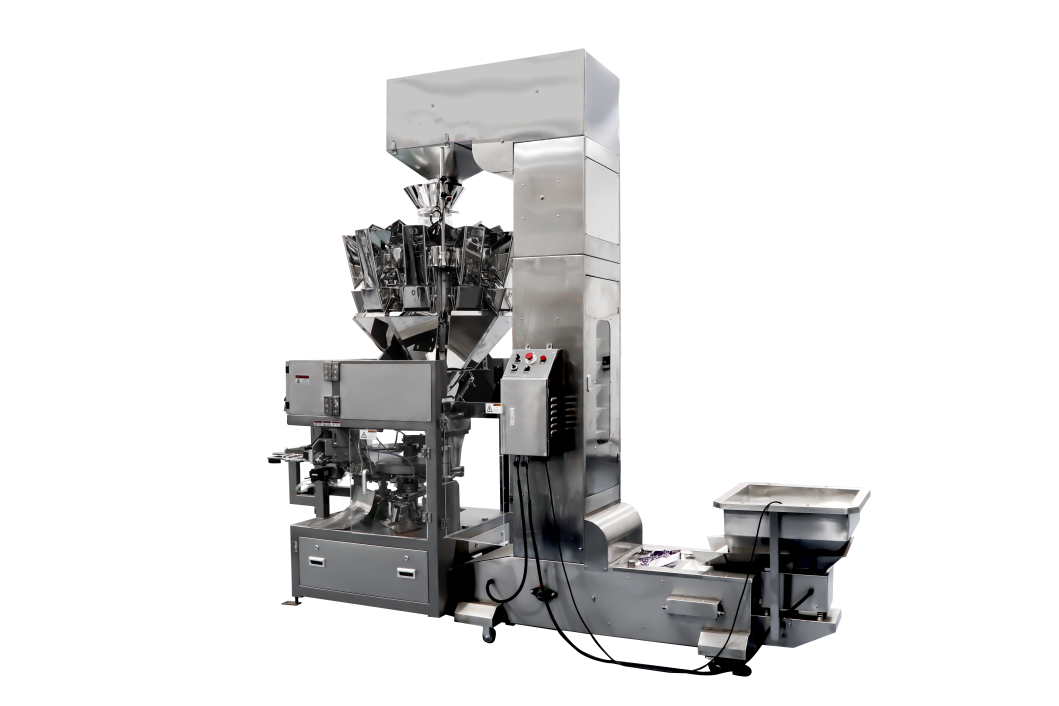

In the realm of packaging solutions, the Z-Type Elevator Pre-Made Pouch Weighing and Packaging Machine stands out as an efficient and versatile choice for handling granular products. This advanced equipment combines precision, speed, and adaptability, making it a valuable asset for industries such as food, snacks, pharmaceuticals, and more.

What is a Z-Type Elevator Pre-Made Pouch Packaging Machine?

This machine is a sophisticated system designed to automate the packaging of granular materials into pre-made pouches. It integrates a Z-type elevator for material feeding, a multi-head weigher for accurate measurement, and a robust pre-made pouch packaging system to handle diverse packaging needs.

Key Components of the System

1. Z-Type Elevator:

The Z-type elevator is responsible for transporting granular materials from the storage hopper to the multi-head weigher. Its efficient design ensures minimal spillage and consistent feeding, optimizing the packaging process.

2. Multi-Head Weigher:

Precision is crucial in packaging. The 10- or 14-head weigher in this system guarantees accurate measurements of the product, maintaining consistency in every package.

3. Pre-Made Pouch Packing Unit:

This unit handles pouch feeding, opening, filling, and sealing. The integration of advanced sealing technologies ensures secure and visually appealing packages.

4. Optional Components:

Metal Detector: Ensures product safety by identifying and rejecting packages containing metal contaminants.

Check Weigher: Verifies the weight of each package, rejecting any that fall outside the specified range.

Date Printer: Prints essential details such as production dates, lot numbers, or expiry dates directly onto the pouch.

Features and Advantages

1. High Automation:

From material feeding to pouch sealing, the machine automates the entire process, significantly reducing labor costs and human error.

2. User-Friendly Operation:

Equipped with a PLC and touch screen interface, the machine allows for easy parameter adjustments and real-time monitoring.

3. Versatility:

The machine can handle a variety of granular products, including nuts, snacks, grains, and candies, and supports multiple pouch types and sizes.

4. Compact Design:

Its integrated structure saves valuable floor space, making it ideal for facilities with space constraints.

5. Durability and Hygiene:

Constructed from food-grade stainless steel, the machine meets strict hygiene standards and ensures long-lasting performance.

Applications

The Z-Type Elevator Pre-Made Pouch Packaging Machine is perfect for packaging a wide range of granular products, including:

1.Snacks such as chips and coated nuts

2. Grains like rice and lentils

3.Confectioneries such as candies and chocolates

4.Pet food and seeds

Why Choose This Machine?

Investing in a Z-Type Elevator Pre-Made Pouch Packaging Machine brings a wealth of benefits to your production line. Its high efficiency, precision, and adaptability make it an excellent choice for businesses aiming to scale up production while maintaining product quality. By integrating advanced technology and thoughtful design, this machine delivers consistent performance, helping manufacturers meet the increasing demands of modern consumers while keeping costs in check.

If you’re interested in exploring how this machine can revolutionize your packaging process, feel free to contact us. Our team of experts is ready to provide tailored solutions that align with your specific needs.

Obtenga el último precio? Le responderemos lo antes posible (dentro de las 12 horas)